Jermy

Jermy

Our goal is to provide to the customers composite solutions, matching the individual needs. Our solutions are products of the newest technology, are durable, aesthetic and at the same time for a reasonable price.

The Jeremy Company began it's activity during ninetieths. First under the name "Jeremi Mroczkowski i ska". As a resault of the expansion to the foreign markets we were forced to change the name of the company to something easier to pronounce - "Jeremy". For the last 10 years we achieved to make a great progress fully surprising the competition. First, our offer contained only one machine of our own production (flour siever) but at the end of 2002 year there are more then 30 differnt machines. All the them are based on our own technology and are produced by our company. This gives record number of 3 production iculcaties per year ! The company creativity is also represented by a great number of the patented technology solutions which are the confirmation ot the uniquity and unchallenged quality of our machines.

Currently "Jeremy Sp. Z o.o." company is the largest bakery equipment producer in Poland and very clearly outdistance polish competition with regards to the range of the products and hi-tech solutions. The above finds it's confirmation in a large number of rewards and favorities and also in a large scale export to demending UE markets, U.S.A, South Korea or Taiwan.

The ideology of our company consist of the three simple words: "quality, reliability, durability". This motto forces all the workers, starting with designers, engineers through merchant section and production to permanent education during everyday work to create, as a resault, products on the highest world level. Proposed solutions are not only the newest technology and designes for the baking and confectioning but also understanding of our customer's needs, flexibility to individual needs and all this for a competitive prices.

0

0

Suitable for many heat sealable and sealable films such as Polypropylene, Polyethylene, laminates, aluminum film, coated and uncoated paper.

Among the most outstanding characteristics is the cam controlled film draw. By the help of this standard feature, beyond doubt the best solution for the film transport, it is possible to cut the film very precisely (tolerances only +/- 0.5mm). Modes of operation: stand alone units as well as integrated in complete production lines for bundling and overwrapping of singular packs or multipacks.

The wide range of possible sizes and the quick change to another size without use of tools are important points in daily operation. Feeding of the product is done either in-line or from one of the two machine sides; standard from left-hand machine side optionally from right-hand side.

The various machines have the following wrapping speeds: up to 45 overwraps, up to 65 overwraps, up to 90 overwraps and up to 200 overwraps per minute.

Machine covering with four doors offering easy access.

Stored program control with display (four lines) and operators guide.

Sizes: Length 75 to 305mm (up to 450mm), width 55 to 205mm (up to 355mm), height 17 to 100mm (up to 175mm).

Film draw: 120 – 660mm.

Film width: 120 – 444mm.

Up to 50 overwraps per minute.

Maximum effect minimum space.

MINIMAX is a strong semi industrial machine designed for using in medium and big bakery.

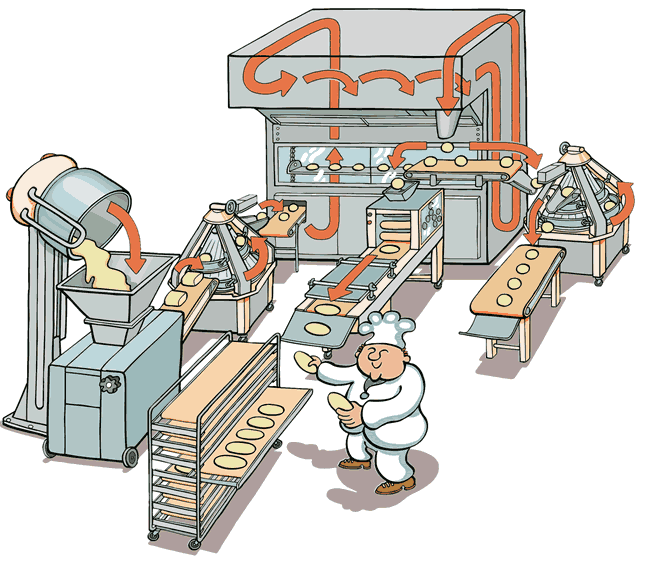

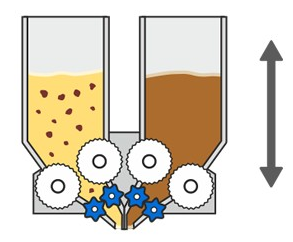

1 - Dough dividers MAGNAT

- divides the dough with big precision in wide weight range

- has got stepless regulation of efficiency (quantity of portions/ hour)

- is solid, simple, silent machine with unique mechanisms construction

- dividing equipment is prepared from special durable materials

- construction permits for easy and fast cleaning

- fixed wheels permit for easy machine relocation

2a. Conical dough rounder ALFA

- Long rounder way 400 or 600 cm

- Regulated weight range (moving troughs) of the rations of the dough (from 60 till 1500g)

- Hot air injection

- Tefloned troughs and conical

- It is possible to install the washers, which make possible to round the dough prepared in 50% from rye flour.

- It is possible to regulate the conical rotation

- Strong industrial construction

2b. Belt rounder BETA

- It is possible to round the dough rations of weight from 200 grams till 1500 grams

- Two options of belt length 1500 and 2000 mm

- Regulated rounding speed

- Ensures correctness of rounding the dough prepared in 90% from rye flour

- Unique construction - the engines were placed in going barrels

- Intermediate proofer RELAX

|

Model |

Quantity of baskets on rowpcs |

Quantity of rowspcs |

Quantity of basketspcs |

PowerkW |

Power supplyV |

Dimensions LxWxHcm |

|

RELAX Uno 6/8 |

6 |

18 |

108 |

0,8 |

400/230V, 50Hz |

175 x 115 x 205 |

|

RELAX Uno 8/18 |

8 |

18 |

144 |

0,8 |

400/230V, 50Hz |

215 x 115 x 205 |

|

RELAX Uno 6/22 |

6 |

22 |

132 |

0,8 |

400/230V, 50Hz |

175 x 115 x 250 |

|

RELAX Uno 8/22 |

8 |

22 |

176 |

0,8 |

400/230V, 50Hz |

215 x 115 x 250 |

4. Dough longmoulder DELTA

- Available with 1 or 2 pressure plates and width of the belt 500 mm or 600 mm.

- Modern and quiet drive of the rolling rollers with help of the rubber belts

- Independent drive of the belt conveyor flight and rolling rollers

- Easy regulation of the pressure plates lifting

- It is possible to regulate the speed of conveyor

- Lateral regulation the length of the dough