Size Reduction – Slicers, Meat Dicers, Shredders,

Meat Grinders, Jet Knives

Size reduction equipment includes slicers, meat dicers, shredders, meat grinders, and jet knives. No machines on the market today can match their versatility or accuracy. These state-of-the-art, continuous flow, fresh or cooked product machines allow our customers to take control of their processing with higher quality product, less handling, improved hygiene, and reduced labor costs -- advantages you need to operate in today's food production environment.

DuraKut™ 6000 2D VFD (or) Servo Dicer

Just like our AdvantEdge dicer series, our DuraKut™ series dicers are designed and built in the USA for complete cutting versatility of fresh, vacuum tumbled, crust frozen or cooked products into cubes or strips. Equipped with VFD or servo drives, the DuraKut 2D dicer‘s powerful and precise indexing movements deliver the very best final product appearance. DuraKut’s robust durable design with tool free disassembly, including removal of the conveyor belt and spiral knife, reduces changeover and sanitation tear down times for different cut sizes. DuraKut frames are built to the latest sanitary standards with open stainless steel channels and no tubular framing. With continuous flow processing and high throughputs, DuraKut models are controlled via a user-friendly HMI with iconbased graphics for the most intuitive interface. DuraKut — CHANGING THE FOOD INDUSTRY ONE CUT AT A TIME.

https://vimeo.com/269638046?embedded=true&source=vimeo_logo&owner=22595589

Features

- Made in USA with centrally sourced parts, field service, and technical support

- VFD driven belts via drum motor (enclosed motor and gear drive)

- Optional product discharge belt conveys finished product directly to dump buggy or takeaway conveyor

- Proprietary spiral knife design reduces fines and product movement during and after slicing along with tool free removal and installation

- 12.5” (317.5mm) wide belt features tensionless belt take-up mechanism for easy belt installation and tool free removal

- Handles product up to 5” (127mm) in height at any length, without the need for pre-cutting. Dice or strip any cut size from .1181” (3mm) up to 4” (101mm).

- Positive belt motion with center drive tensionless belt prevents cracking due to over tensioning

- Continuous flow processing design allows for smooth integration into any processing line. No need for batching.

- Controlled via a user-friendly HMI with icon-based graphics for the most intuitive interface for multilingual workforces

- Open design and fewer parts reduce teardown, sanitation and reassembly time

- Gang knife cartridge can be easily mounted and removed with tool free disassembly

- Hinged covers and door panels with no external hinges

- EWON Wi-Fi capable (standard on servo)

- CE Compliant

- Optional horizontal slicing attachment for 3D cuts

DuraKut™ Horizontal Slicer

Features

- Made in the USA with centrally located parts, field service, and technical support

- 12.5″ (317.55mm) wide horizontal blades with tool free removal

- Handles product up to 5″ (127mm) in height at any length, without the need for pre-cutting. Horizontally slices product from 1/4″ (6.35mm) up to 1″ (25mm) thickness.

- Open design and fewer parts reduce teardown, sanitation and reassembly time

- Ultra-hygienic design with open stainless steel channels (no enclosed) tubular framing, sloped surfaces, no lamination points, etc.

- Allen-Bradley HMI touch screen

Features

- Our one-dimensional slicer is designed for slicing whole muscle, fresh or cooked meats and portioning other products into strips or steaks. Slices accurately, even on the most delicate products, as well as the toughest meats.

- Patented cutting action uses conveyors to hold and control the product. Our low rpm, stay-sharp blades produce accurate, consistent sizing without ripping or tearing of product. This creates minimal fines which provide the best quality cut.

- Processes product up to 5″ in height at any length without the need for pre-cutting.

- Designed for minimal moisture loss, product is fed and discharged gently which minimizes breakage and maximizes dice yield.

- Designed to process ‘tough’ or ‘fragile’ products.

- Continuous flow processing design, allows for a smooth integration into any processing line. No need for batching.

- Slice chilled product down to 25° F or fresh product at refrigerated temperatures or fully cooked hot right from the oven. No need to chill or temper the meat to cut fresh.

- Full range of slicing from 1/16″ slices to over 3″ on the same machine.

- Made in the USA.

AE 5000 2D Dicer

Our AE 5000 2D Dicer provides cuts to length and width spec, in sequence (leaving natural height/thrid dimension in tact). Known as a meat dicer, this model processes whole muscle cooked or fresh log meats and other products by slicing, dicing, and strip cutting on one unit.

Features

- Our patented cutting action uses conveyors to hold and control the product. Our low rpm, stay-sharp blades produce accurate, consistent sizing without ripping or tearing of product. This creates minimal fines which provide the best quality cut available.

- Processes product up to 5″ in height at any length, without the need for pre-cutting.

- Designed for minimal moisture loss, product is fed and discharged gently which minimizes breakage and maximizes dice yield.

- Designed to process tough, fatty products with sinew or gristle. Slice, dice, strip, maintain grain orientation and cut any size from 1/8″ to 4.”

- Continuous flow processing design allows for a smooth integration into any processing line. No need for batching.

- Capable of processing crust-frozen (hard outsdide, soft in the center), fresh product at refrigerated temperates, or fully cooked (up to 190 deg F) product right from the oven. There is no need to chill or temper the meat in order to dice/slice effectively.

- Slice, dice, strip, and maintain grain orientation. Provides full range of slicing/dicing from 1/8″ to over 3″ on the same machine.

- Made in the USA.

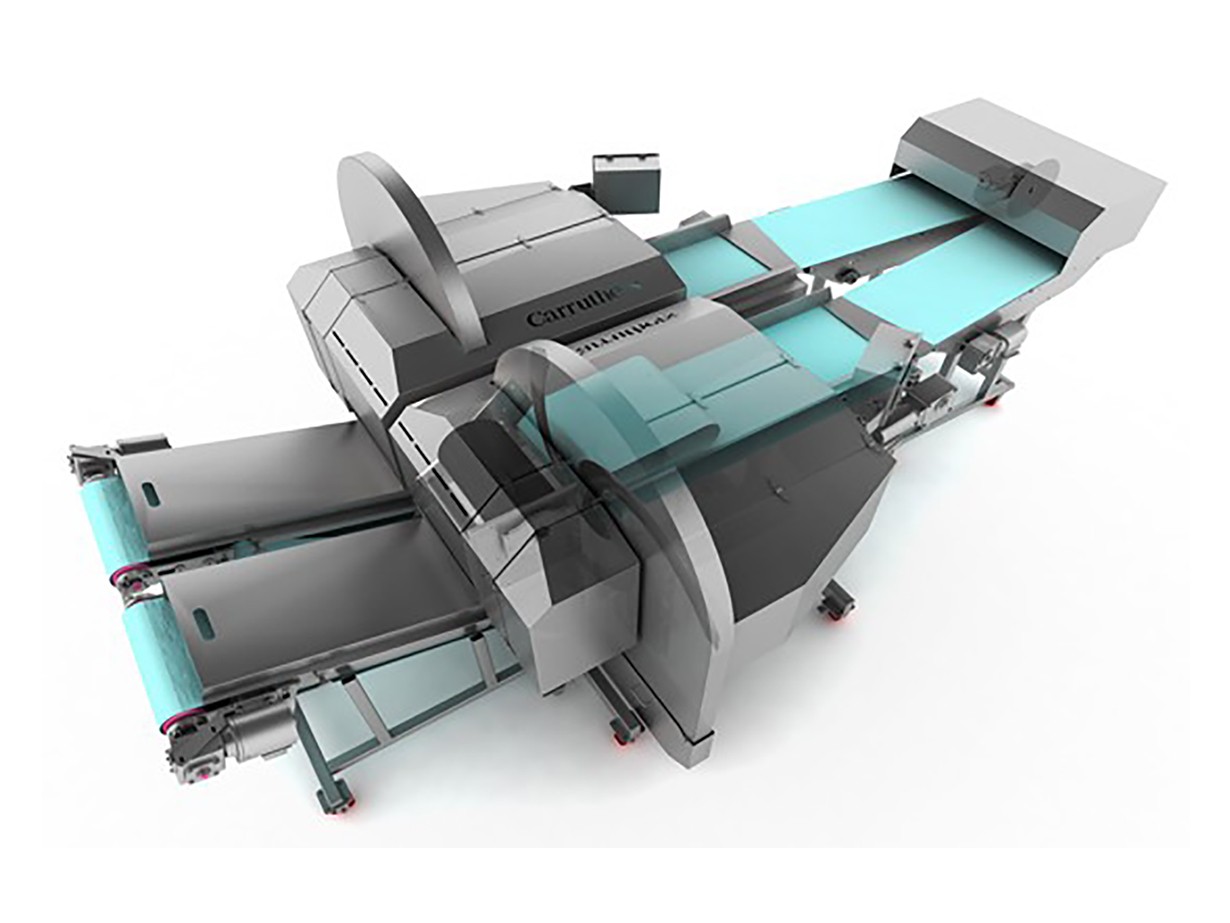

AE 5000 2D 20″ Twin Dicers

Do you need to one- or two-dimensionally dice or strip-cut hot cooked meats after exiting a 40" spiral or linear oven belt? If so, Marlen has the solution for your plant! By combining two 20" wide AE 5000 tandem dicers – in mirror image – continuously fed product exiting an oven belt can be easily and seamlessly transferred into our AE 5000 series dicers. In combination, the “tried and true” AE 5000’s offer high volume with their combined 40" belting. Product is conveyed from the continuous oven directly into a product slitter which utilizes a circular blade to cut/divert/divide the product into two streams. Final dice or strip-cut product is then transferred to downstream processing (e.g. chiller/freezer) via the integrated incline conveyor. Final results are higher quality product, less handling, improved hygiene, and reduced labor costs – advantages you need to operate in today’s food production environment.

Features

- Circular and spiral blades are built to last and are easily sharpened for multiple uses resulting in a longer wear life and blades that won’t break

- Keeps “sheet” style meat intact to minimize fines

- Compact design requires minimal floor space and allows seamless transfer of product from oven to chiller

- 20,000 pounds per hour throughput based on 1″ x 1″ x natural height finished dice

- Optionally engineered with high temperature plastics to withstand up to 180 deg F products

- Product up to 5-inches in height and at any length can be diced or strip-cut without the need for pre-cutting

- Gentle feeding and discharging keeps moisture in the product which minimizes breakage and maximizes dice yields for the best possible appearance and cut

- Our AdvantEdge dicers are designed to handle hot tough, fatty products with sinew, gristle or connective tissue, resulting in clean cut product

- Made in USA

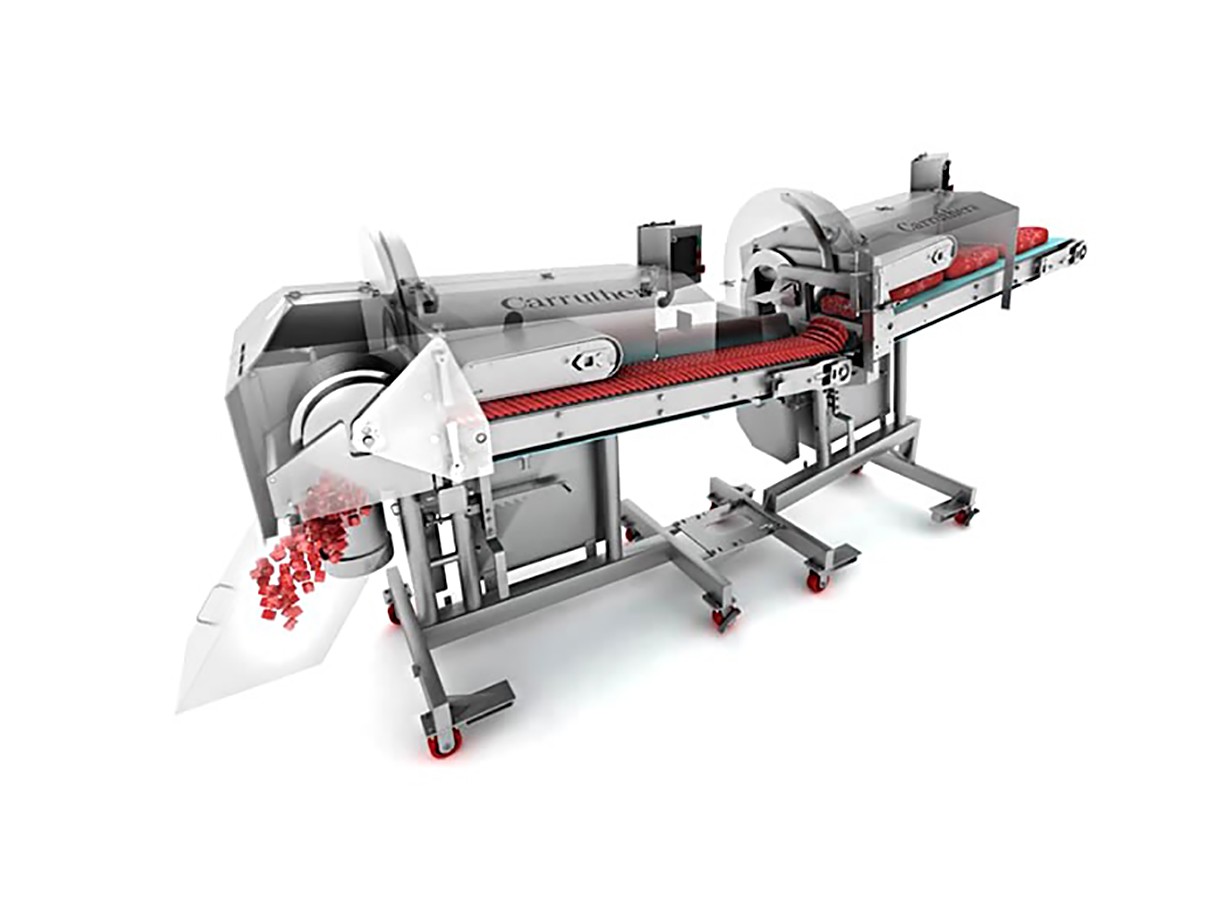

AE 5000 3D Dicer

AE 5000 3D Dicer is designed for three-dimensional cubing. A combination of the 1D Slicing and 2D Dicing models provides complete versatility for cubing of whole muscle, cooked or fresh log meats and other products.

Features

- Our 3D processing line is a combination of our 1D and 2D models to continuously cube large primal cuts or deli logs. The sliced product from the 1D slicer is automatically transferred to the 2D dicer to complete the 3D process. These machines can also be separated for independent runs.

- Processes product up to 5″ in height at any length. Designed to accept large primal cuts or full size deli logs without the need for pre-cutting.

- Our patented cutting action using conveyors to hold and control the product. Our low rpm stay-sharp blades produce accurate and consistent sizing without ripping or tearing of product. This creates minimal fines which provide the best quality cut.

- Our AE 5000 3D Dicer accurately cuts the most delicate products, as well as the toughest meats into strips, steaks, cubes and dices.

- One, two or three dimensional slicing, dicing, stripping, cubing while maintaining grain orientation and cut any size from 1/8″ to 4″.

- Designed for minimal moisture loss, product is fed and discharged gently which minimizes breakage and maximizes dice yield.

- Our continuous flow processing design allows for a smooth integration into any processing line. No need for batching.

- Dices tough products having sinew or gristle such as beef brisket, beef silverside, beef top rounds, or cooked meats. Also Dices fragile products such as cooked beef, chicken, or turkey logs. Finished product is clean cut with no connective pieces, no loss of structure, with minimal moisture loss.

- Cube, slice, dice, strip, and maintain grain orientation. Provides full range of slicing/dicing from 1/8″ to over 3″ on the same machine.

- Cube chilled product down to 25° F or fresh product at refrigerated temperatures or fully cooked hot right from the oven. No need to chill or temper the meat.

- Made in the USA.

AE Logger Meat Portioner

Programmable one-dimensional meat portioner for deli meats, deli loafs or snack sticks. Specify lengths or numbers of lengths for portion control accuracy of 1/16", and automatically remove ends and clips.

Features

- AE Logger is an one-dimensional portioner that provides processors with improved processing speed and lower labor costs.

- Patented cutting action allows for clean, precise cuts on a wide range of products such as deli meats, loaves, processed logs, snack sticks, and more.

- Portion control design assures maximum yields by achieving cut length accuracies to within 1/16.”

- The AE Logger is designed and constructed to make operation and maintenance easier to maximize uptime.

- Fully programmable cut sizes of any length

- Ends reject capability

- Product length sensing

- Auto-bar code recognition for fast cut pattern recall

- Specify lengths or numbers of lengths for portion control accuracy

- Fully sealed belts

- Stainless steel drive pulleys

- Direct drive Servo motors

- Marlen International also offers Carruthers parts for the AE Logger and Portioner

- Made in the USA

XT Strip Cutter

Our Marlen XT Series Strip Cutters are designed for continuous strip cutting of raw (or fresh) beef, pork, poultry and veal. The machine can be fed manually or placed inline where there is continuous product flow. Your ideal solution for faster, gentler and more economical strip cutting.

Features

- Three belt widths available: 13” (330mm), 26” (660mm) or 39” (990mm)

- Simple 3-position switch for belt and blade speeds (15-ft, 30-ft or 60-ft per minute)

- Direct drive stainless steel motors and gearbox for belt and blade drives

- Ultra-hygienic stainless steel anti-slip mesh belting with self-tracking feature

- Sloped top Patented sealed electrical cabinet enclosure for water runoff

- 8” (203mm)) diameter blades for 4” max. product height of 2.75”

- Flexible design handles strip cuts from ½” (6.35mm) to 3” (76mm) and processing temperatures from 28°F (-2°C) to 60°F (15°C)

- Robust stainless steel welded tubular frame

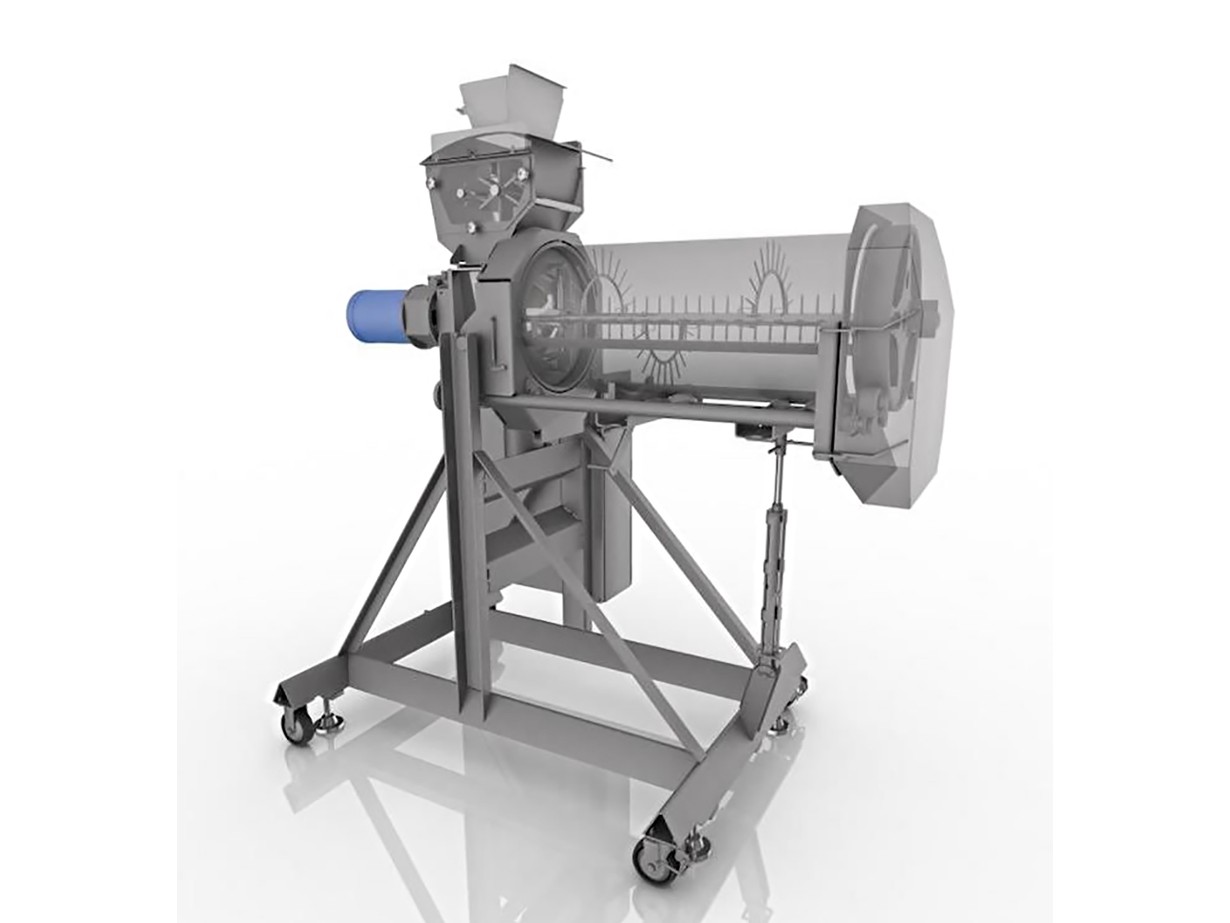

Features

- Carruthers Auto-Shredder is a continuous flow machine allowing for a smooth integration into any processing line.

- Designed to easily break down tough products such as cooked beef logs with the same efficiency as it does softer products such as cooked chicken breast.

- Optional pre-break system that serves as both a product metering device and initial size reduction tool which minimizes breakage and maximizes yield.

- All mechanisims (auger, main spindle, drum, pre-break and shredding cage) function via the shredder’s direct drive for increased efficiency and a longer wear life.

- Variable frequency drive speed control for greater product flexibility.

- A retractable drum, quick release radials and flight rods as well as a removable drive shaft and auger provides easy access to the machine’s components for improved sanitation and better hygiene.

- Constructed of stainless steel, the Auto-Shredder also features a number of angled surfaces and reduced hollow zones for improved water run off to prevent microbial buildup.

- Carruthers Shredders are designed and constructed to make operation and maintenance easier to maximize uptime.

- Innovative design

- Controllable product appearance fine to coarse

- Multi-product versatility

- Fast, high volume processing

- Low maintenance cost

- Marlen International also offers Carruthers parts for the Auto-Shredder

- Made in the USA

Tabletop Meat Shredder

Our economical, space-saving tabletop meat shredder is designed to efficiently shred beef, poultry, pork, and alternative meats to produce "hand pulled" products without the expense of intensive manual labor. Load your product in the drum and achieve results within minutes.

Features

- Batch shreds up to 20 pounds of product in 1-5 minutes

- Features push-button controls and an analog timer which simplifies operation

- Low profile and compact design accommodates space constraints and provides smooth unit mobility

- The Tabletop Meat Shredder is a batch process designed to give cooked meat fibers that “Hand-Pulled” look and appearance

- Ideal for restaurants or small to mid-sized processors producing small batches of shredded cooked meats

- The Tabletop Meat Shredder is designed and constructed to maximize uptime through easy operation and maintenance

- Its ease of operation and quick changeover saves time and labor costs

- Quick processing times

- Consistent product shredding; enables control of product appearance from fine to coarse shredded meats

- Low labor costs

- Easy cleanup; durable stainless steel construction with fully removable components (t-arm, flights, and drum) for full wash down and sanitation. USDA approved.

- Low maintenance cost

- Made in the USA

Vari-Kut In-line Electric Meat Grinder

Marlen's Vari-Kut electric in-line meat grinder is a particle reduction system with variable speed control. It is regarded as one of the industry's best grinding solutions available.

Features

- Marlen’s versatile electric in-line Grinder can be used in a variety of processing applications. When fed by a Marlen pump, the Vari-Kut produces improved particle definition, reduced smearing and cell damage, and only minimal temperature rise.

- The grinder housing (elbow) is made of heavy stainless steel design that ensures years of dependable service with no rust

- Cutting speed is controlled by an electric motor which results in complete control of product texture and cut length to maximize product appearance.

- The Vari-Kut uses readily available standard plates and knives. Available in two sizes (8-5/8″ and 11″).

- The in-line grinder head can be rotated a full 360 degrees to allow an infinite variety of processing applications. It can be mounted at the pump or at a remote location, and easily mates with ancillary equipment. An optional automatic bone-collect system removes objectionable fragments, and a vacuum option can be added to help improve product color and shelf life.

- The knife blades are designed to deliver a precise, clean cut that produces consistent particle definition, without smear. The single cut design results in decreased drying times and increased shelf life.

- The in-line Grinder offers continuous in-line bone collection to produce a top quality product

- Single cut design gives processors a consistent, clean cut and formulation savings

- Marlen International also offers Marlen parts for in-line grinders

- Made in the USA

Vari-Kut In-Line Meat Grinder

Marlen's Vari-Kut hydraulic in-line meat grinder is a particle reduction system with variable speed control. It is regarded as one of the industry's best grinding solutions available.

Features

- Marlen’s versatile hydraulic in-line Grinder can be used in a variety of processing applications. When fed by a Marlen pump, the Vari-Kut produces improved particle definition, reduced smearing and cell damage, and only minimal temperature rise.

- The grinder housing (elbow) is made of heavy stainless steel design that ensures years of dependable service with no rust

- Cutting speed is controlled by an electric motor which results in complete control of product texture and cut length to maximize product appearance.

- The Vari-Kut uses readily available standard plates and knives. Available in two sizes (8-5/8″ and 11″).

- The In-Line grinder head can be rotated a full 360 degrees to allow an infinite variety of processing applications. It can be mounted at the pump or at a remote location, and easily mates with ancillary equipment. An optional automatic bone-collect system removes objectionable fragments, and a vacuum option can be added to help improve product color and shelf life.

- The knife blades are designed to deliver a precise, clean cut that produces consistent particle definition, without smear. The single cut design results in decreased drying times and increased shelf life.

- The In-Line Grinder offers continuous in-line bone collection to produce a top quality product

- Single cut design gives processors a consistent, clean cut and formulation savings

- Marlen International also offers Marlen parts for in-line grinders

- Made in the USA

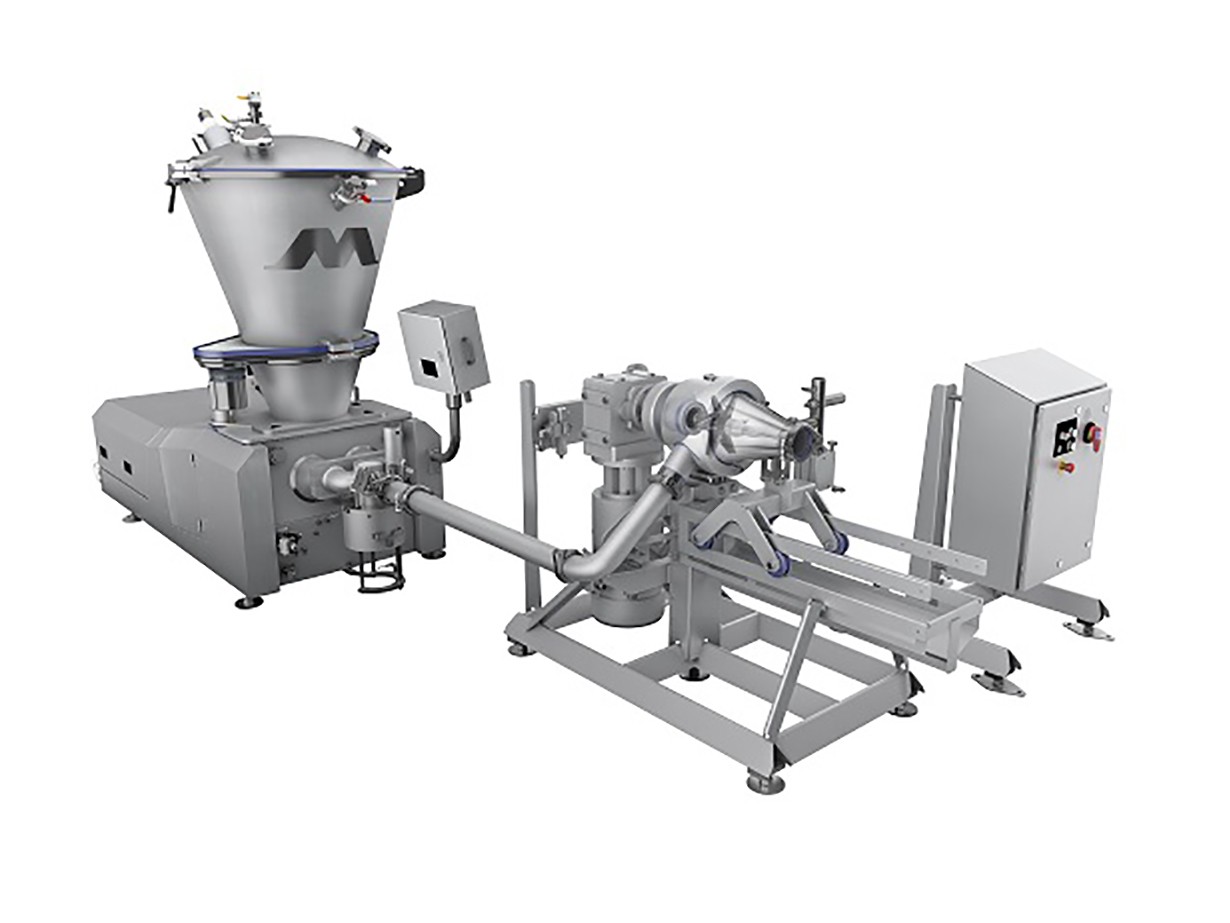

Jet Knife Forming System

Features

- The Jet Knife blades are designed to deliver a precise, clean cut that produces consistent particle definition, without smear. The single cut design results in decreased drying times and increased shelf life.

- The variable speed hydraulic knife motor permits control of particle cut length which helps maintain control of particle length even when feeding multiple downstream machines

- The Jet Knife forming system is designed to give a cleaner particle release

- Designed to be configured with one uniform size and shape, or each individual hole can be different. This allows the machine to be tailored to fit your needs.

- Designed specifically for forming individual particulates such as Pizza Toppings, Meatballs, Chili, and Pet Food

- Marlen International also offers Marlen parts for the Jet Knife forming system

- Made in the USA

Knife Sharpener

Using our newly designed CE compliant knife sharpener will keep circular blades in prime condition and optimize the performance of your Marlen dicer. This circular knife sharpener is engineered to follow the exact contour of the edge profile, leaving no room for error.

Features

• Sharpens 8-, 12-, and 14-inch circular gang blades for Marlen dicers

• Simple to operate and easy to maintain

• Quick-change grinding stones (360 grit & 80 grit available)

• Increases yields, reduces fines and minimizes parts cost

• Tabletop, plug-n-play design (110 Volt)

• CE Compliant

.jpg)

Benefits of Size Reduction

Highly engineered continuous flow solutions for fresh or cooked product allow our customers to take control of their size reduction needs with premium quality, improved shelf life, and better yield.

- Versatile solutions for a broad variety of applications.

Designed and built for complete cutting versatility of fresh, vacuum tumbled, crust frozen or cooked products.

- Very best product appearance.

Unique cutting action produces accurate, consistent sizing without tearing the product.

- Ultra-hygienic designs for utmost food safety.

Machines are built to the latest sanitary standards with open stainless steel channels and no tubular framing.