Vacuum Stuffing, Pumping & Portioning

Marlen OPTI series vacuum stuffing and pumping machines feature twin piston pumping systems with a variety of hopper options designed to match product requirements. This series is available in multiple capacities ranging from 10,000 to 34,000 lbs. per hour production rates. Additionally, we offer a complete line of portioning equipment to satisfy almost any scenario. Exact weight, volumetric, dynamic and transducer portioners are available options designed to fit your application.

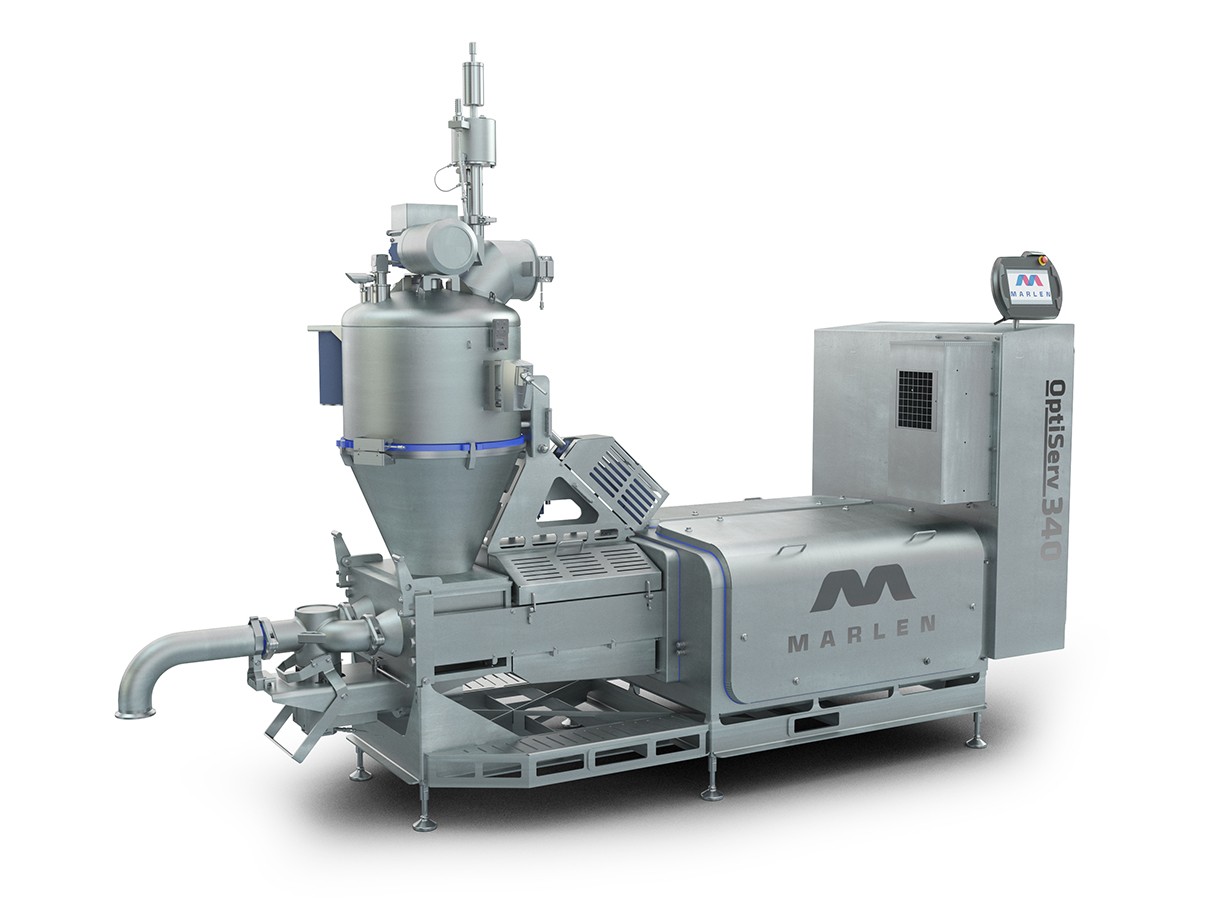

With the pumping process powered entirely by servo motor technology, Marlen's OptiServ series pumps deliver exemplary high quality output while dramatically reducing the complexity and cost of operating at peak performance levels. With unmatched product quality and appearance the industry has come to expect from Marlen, the OptiServ series is designed to lower total cost of ownership and deliver significant savings.

https://player.vimeo.com/video/362301994?autoplay=1

Features

- Highest vacuum level in the industry (<4 TORR) for maximum removal of entrapped air

- Product throughput up to 34,000 lbs (15,422 kg) per hour at 125 PSI

- Selectable modes of operation: Constant pressure (surge free continuous flow) or speed control, both with superior portion accuracy

- Engineered with regenerative servo drives for maximum efficiency and over 40% reduction in energy over hydraulic models

- Energy-efficient air cooled system – no water required

- Best-in-class “customer inspired” hygienic design

- Featuring no-leak, patent pending sealed electrical box with multiple sanitary features

- Improved ergnomic design for quick, no tool 3-minute assembly/disassembly and optimal operator safety

- Smart, highly intuitive icon based HMI, making operation extremely user-friendly for multi-lingual workforces

- Designed with significantly less replacement and wear parts for best value, increased uptime, and lower total cost of ownership

- Product guides available in various styles to match application needs

- Nearly silent operation

- CE version available

Opti 100 Vacuum Stuffer & Pump

Features

- Simplicity; no digital controls

- All the basics of a twin piston Marlen pump at a fraction of the cost

- Small footprint and easily portable. Low profile design accommodates space constraints and heavy-duty casters provide smooth unit mobility

- 10,000 lbs pumping capacity with a maximum of 250 psi pumping pressure

- Marlen’s unique high-differential vacuum ensures maximum removal of entrapped air resulting in denser product, more accurate portion control, and longer shelf life

- Patented, hydraulically-driven front valve delivers positive shifting for continuous, even product flow, and more accurate portion weight control

- Twin-piston pumping system designed to gently deliver products to downstream processes. The zero-slip design maintains product integrity for products ranging from the highly abrasive to whole muscle. The system is gentle on your products and reduces wear on the unit, extending its life.

- Hopper options include standard open top hopper to full vacuumizer hoppers with augers for load assist for complete versatility

- Designed for easy operation & control

- Externally-adjustable diffuser valve (Patented)

- Push-button controls

- Proven twin-piston design

- Largest product openings

- Zero-slip design eliminates product degradation

- Minimal product damage and fewer cuts

- Designed to reduce the need for downstream accumulators or bypass

- Precise metered flow or constant pressure control

- Built to USDA accepted standards

- Smaller number of parts simplifies cleanup

Opti 120 HP Vacuum Stuffer & Pump

.jpg)

Features a twin-piston vacuum stuffing and pumping system with a variety of hopper options designed to match product requirements. Available in three models with maximum capacity of 20,000 lbs per hour, 500 psi pumping pressure. Ideal for higher speed output and higher pumping pressure applications. Can be equipped with an optional hydraulic fluid cooling unit without the need for water cooling.

Features

- Available in high speed or high pressure pumping versions

- Ideal for higher speed pumping output with maximum capacity 20,000 lbs per hour, 250 psi pumping pressure

- Ideal for higher pumping pressure applications with maximum capacity 12,000 lbs per hour, 500 psi pumping pressure.

- Programmable Logic Controller with optional closed-looped feedback system can be customized with a variety of packages to meet your specific needs

- Marlen’s proven twin-piston pumping system design; largest product opening on the market

- Twin position and sleeve design allows for the industry’s highest vacuumizing pumpingavailable eliminating the need for inferior dual stage vacuumization process

- Designed with two modes of pumping for better pressure control or controlled flow rate which allows the plant to tailor the equipment to the application

- Opti vacuum fillers and stuffing pumps can achieve the highest vacuumization in the industry for excellent color retention results

- Patented design eliminates metal-to-metal contact within the pump chamber which eliminates regular costly part replacement and downtime.

- Twin-Piston Pumping Chamber features a 10° incline that increases product flow into the pumping chamber. Easier loading into the pumping chamber ensures maximum operating efficiencies.

- Built in self diagnostic feature helps reduce down time

- Unobstructed patented 4 inch hydraulically driven front valve for positive shifting and even product flow

- Opti vacuum fillers and stuffing pump design reduces loose parts and simplifies cleaning

- Hopper options include standard open top hopper to full vacuumizer hoppers with augers for load assist for complete versatility

- High differential vacuum stuffers on vacuumized units ensures maximum removal of entrapped air for better weight control, shelf life, and casing savings

- Patented externally adjustable diffuser valve with 8 inch inlet enables the Opti-Series to maximize the product’s exposure to vacuum

- Power-Tilt Hopper is hydraulically operated from the touch pad control panel for full access into all product areas during cleanup. Tilts back with the touch of a finger.

- Designed for easy operation and control with diagnostic capabilities

- State-of-the-art control panel

- Large recipe storage capacity

- Foreign language customizing

- Externally-adjustable diffuser valve (Patented)

- Push-button controls

- Proven twin-piston design

- Largest product openings

- Zero-slip design eliminates product degradation

- Minimal product damage and fewer cuts

- Designed to reduce the need for downstream accumulators or bypass

- Precise metered flow or constant pressure control

- Built to USDA accepted standards

- Smaller number of parts simplifies cleanup

- Marlen International also offers Marlen parts

- Made in the USA

Opti 200 Outboard Vacuum Stuffer & Pump

Features a twin-piston vacuum stuffing and pumping system with a variety of hopper options designed to match product requirements. Maximum capacity 20,000 lbs per hour, 250 psi pumping pressure. Ideal for applications requiring higher speed output. Can be equipped with an optional hydraulic fluid cooling unit without the need for water cooling.

Features

- Totally self-contained vacuumize filler 25 horsepower hydraulic unit, 5 horsepower 71 cfm vacuum pump, air cooled, including motor starters

- 20,000 lbs pumping capacity with a maximum of 250 psi pumping pressure

- Marlen’s proven twin-piston pumping system design; largest product opening on the market

- Twin position and sleeve design allows for the industry’s highest vacuumize pumping available eliminating the need for inferior dual stage vacuumization process

- Designed with two modes of pumping for better pressure control or controlled flow rate which allows the plant to tailor the equipment to the application

- Opti Vacuum Fillers and Suffing Pumps can achieve the highest vacuumization in the industry for excellent color retention results

- Twin-Piston Pumping Chamber features an 10° incline that increases product flow into the pumping chamber. Easier loading into the pumping chamber ensures maximum operating efficiencies.

- Marlen’s patented design eliminates metal-to-metal contact within the pump chamber which eliminates regular costly part replacement and downtime

- State-of-the-art control panel with built-in self-diagnostic feature helps reduce downtime

- Unobstructed patented 4 inch hydraulically driven front valve for positive shifting and even product flow

- Opti Vacuum Fillers and Suffing Pumps design reduces loose parts and simplifies cleaning

- Hopper options include standard open top hopper to full vacuumizer hoppers with augers for load assist for complete versatility

- High differential vacuum stuffers on vacuumized units ensures maximum removal of entrapped air for better weight control, shelf life, and casing savings

- Patented externally adjustable diffuser valve with 8 inch inlet enables the OPTI-Series to maximize the product’s exposure to vacuum

- Power-Tilt Hopper is hydraulically operated from the touch pad control panel for full access into all product areas during cleanup

- Designed for easy operation and control with diagnostic capabilities

- State-of-the-art control panel

- Large recipe storage capacity. Easy screen navigation. 8.4″ touch screen.

- Foreign language customizing

- Externally-adjustable diffuser valve (Patented)

- Push-button controls

- Proven twin-piston design

- Largest product openings

- Zero-slip design eliminates product degradation

- Minimal product damage and fewer cuts

- Designed to reduce the need for downstream accumulators or bypass

- Precise metered flow or constant pressure control

- Built to USDA accepted standards

- Smaller number of parts simplifies cleanup

- Marlen International also offers Marlen parts

- Made in the USA

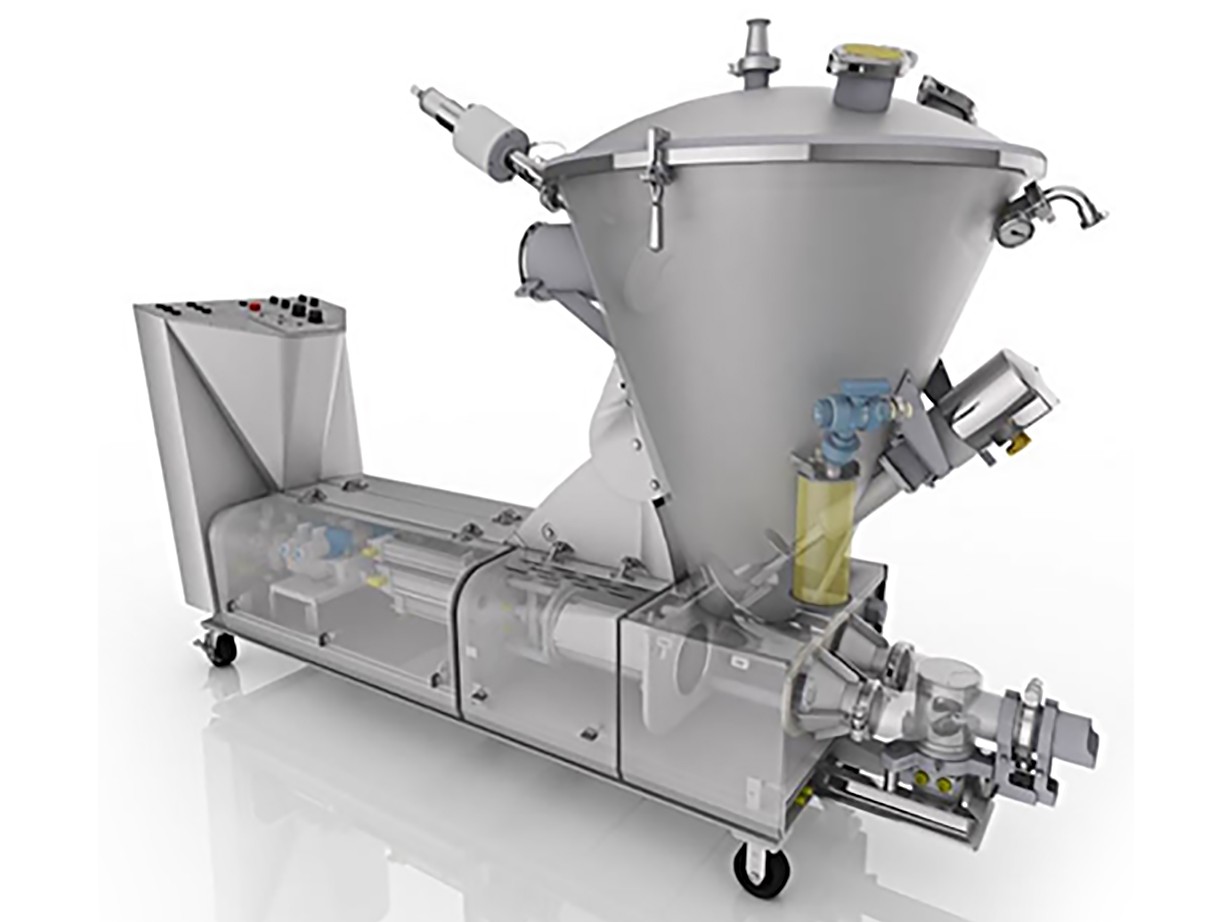

Opti 200 Inboard Vacuum Stuffer & Pump

Features a twin-piston vacuum stuffing and pumping system with a variety of hopper options designed to match product requirements. Maximum capacity 20,000 lbs per hour, 250 psi pumping pressure. Ideal for applications requiring higher speed output. Can be equipped with an optional hydraulic fluid cooling unit without the need for water cooling.

Features

- Totally self-contained vacuumize filler 25 horsepower hydraulic unit, 5 horsepower 71 cfm vacuum pump, air cooled, including motor starters

- 20,000 lbs pumping capacity with a maximum of 250 psi pumping pressure

- Marlen’s proven twin-piston pumping system design; largest product opening on the market

- Twin position and sleeve design allows for the industry’s highest vacuumize pumping available eliminating the need for inferior dual stage vacuumization process

- Designed with two modes of pumping for better pressure control or controlled flow rate which allows the plant to tailor the equipment to the application

- Opti Vacuum Fillers and Suffing Pumps can achieve the highest vacuumization in the industry for excellent color retention results

- Twin-Piston Pumping Chamber features an 10° incline that increases product flow into the pumping chamber. Easier loading into the pumping chamber ensures maximum operating efficiencies.

- Marlen’s patented design eliminates metal-to-metal contact within the pump chamber which eliminates regular costly part replacement and downtime

- State-of-the-art control panel with built-in self-diagnostic feature helps reduce downtime

- Unobstructed patented 4 inch hydraulically driven front valve for positive shifting and even product flow

- Opti Vacuum Fillers and Suffing Pumps design reduces loose parts and simplifies cleaning

- Hopper options include standard open top hopper to full vacuumizer hoppers with augers for load assist for complete versatility

- High differential vacuum stuffers on vacuumized units ensures maximum removal of entrapped air for better weight control, shelf life, and casing savings

- Patented externally adjustable diffuser valve with 8 inch inlet enables the OPTI-Series to maximize the product’s exposure to vacuum

- Power-Tilt Hopper is hydraulically operated from the touch pad control panel for full access into all product areas during cleanup

- Designed for easy operation and control with diagnostic capabilities

- State-of-the-art control panel

- Large recipe storage capacity. Easy screen navigation. 8.4″ touch screen.

- Foreign language customizing

- Externally-adjustable diffuser valve (Patented)

- Push-button controls

- Proven twin-piston design

- Largest product openings

- Zero-slip design eliminates product degradation

- Minimal product damage and fewer cuts

- Designed to reduce the need for downstream accumulators or bypass

- Precise metered flow or constant pressure control

- Built to USDA accepted standards

- Smaller number of parts simplifies cleanup

- Marlen International also offers Marlen parts

- Made in the USA

Opti 280 Vacuum Stuffer & Pump

Features a twin-piston vacuum stuffing and pumping system with a variety of hopper options designed to match product requirements. Maximum capacity 28,000 lbs per hour, 500 psi pumping pressure. Ideal for all applications. Can be equipped with an optional hydraulic fluid cooling unit without the need for water cooling.

Features

- 28,000 lbs pumping capacity with a maximum of 500 psi pumping pressure

- Marlen’s proven twin-piston pumping system design; largest product opening on the market

- Twin position and sleeve design allows for the industry’s highest vacuumizing pumpingavailable eliminating the need for inferior dual stage vacuumization process

- Designed with two modes of pumping for better pressure control or controlled flow rate which allows the plant to tailor the equipment to the application

- OPTI vacuum fillers and stuffing pumps can achieve the highest vacuumization in the industry for excellent color retention results

- Twin-Piston Pumping Chamber features an 10° incline that increases product flow into the pumping chamber. Easier loading into the pumping chamber ensures maximum operating efficiencies.

- Marlen’s patented design eliminates metal-to-metal contact within the pump chamber which eliminates regular costly part replacement and downtime

- State-of-the-art control panel with built-in self-diagnostic feature helps reduce downtime

- Unobstructed patented 4 inch hydraulically driven front valve for positive shifting and even product flow

- OPTI vacuum fillers and stuffing pumps design reduces loose parts and simplifies cleaning

- Hopper options include standard open top hopper to full vacuumizer hoppers with augers for load assist for complete versatility

- High differential vacuum stuffers on vacuumized units ensures maximum removal of entrapped air for better weight control, shelf life, and casing savings

- Patented externally adjustable diffuser valve with 8 inch inlet enables the OPTI-Series to maximize the product’s exposure to vacuum

- Power-Tilt Hopper is hydraulically operated from the touch pad control panel for full access into all product areas during cleanup

- Designed for easy operation and control with diagnostic capabilities.

- State-of-the-art control panel

- Large recipe storage capacity. Easy screen navigation. 8.4″ touch screen.

- Foreign language customizing

- Externally-adjustable diffuser valve (Patented)

- Push-button controls

- Proven twin-piston design

- Largest product openings

- Zero-slip design eliminates product degradation

- Minimal product damage and fewer cuts

- Designed to reduce the need for downstream accumulators or bypass

- Precise metered flow or constant pressure control

- Built to USDA accepted standards

- Smaller number of parts simplifies cleanup

- Marlen International also offers Marlen parts for the OPTI 280 Vacuum Filler and Stuffing Pump

- Made in the USA

Opti 340 Vacuum Stuffer & Pump

Features a twin-piston vacuum stuffing and pumping system with a variety of hopper options designed to match product requirements. Maximum capacity 34,000 lbs per hour, 250 psi pumping pressure. Ideal for higher volume applications. Can be equipped with an optional hydraulic fluid cooling unit without the need for water cooling.

Features

- Able to pump large particulates at rates up to 34,000 lbs per hour with a maximum of 250 psi vacuumize pumping pressure

- Marlen’s proven twin-piston pumping system design; largest product opening on the market

- Twin position and sleeve design allows for the industry’s highest vacuumizing pumping available eliminating the need for inferior dual stage vacuumization process

- Designed with two modes of pumping for better pressure control or controlled flow rate which allows the plant to tailor the equipment to the application

- OPTI vacuum fillers and stuffing pumps can achieve the highest vacuumization in the industry for excellent color retention results

- Marlen’s patented design eliminates metal-to-metal contact within the pump chamber which eliminates regular costly part replacement and downtime

- Twin-Piston Pumping Chamber features an 10° incline that increases product flow into the pumping chamber. Easier loading into the pumping chamber ensures maximum operating efficiencies.

- State-of-the-art control panel with built-in self-diagnostic feature helps reduce downtime

- Unobstructed patented 4 inch hydraulically driven front valve for positive shifting and even product flow

- OPTI vacuum fillers and stuffing pump design reduces loose parts and simplifies cleaning

- Hopper options include standard open top hopper to full vacuumizer hoppers with augers for load assist for complete versatility

- High differential vacuum stuffers on vacuumized units ensures maximum removal of entrapped air for better weight control, shelf life, and casing savings

- Patented externally adjustable diffuser valve with 8 inch inlet enables the Opti-Series to maximize the product’s exposure to vacuum

- Power-Tilt Hopper is hydraulically operated from the touch pad control panel for full access into all product areas during cleanup

- Designed for easy operation and control with diagnostic capabilities

- State-of-the-art control panel

- Large recipe storage capacity. Easy screen navigation. 8.4″ touch screen.

- Foreign language customizing

- Externally-adjustable diffuser valve (Patented)

- Push-button controls

- Proven twin-piston design

- Largest product openings

- Zero-slip design eliminates product degradation

- Minimal product damage and fewer cuts

- Designed to reduce the need for downstream accumulators or bypass

- Precise metered flow or constant pressure control

- Built to USDA accepted standards

- Smaller number of parts simplifies cleanup

- Marlen International also offers Marlen parts for the OPTI 340 Vacuum Filler and Stuffing Pump

- Made in the USA

Opti-Xtrude Extruder

Marlen’s Opti-Xtrude Extruder is designed for the extrusion of viscous, shear-sensitive corn masa or potato starch. Our Opti-Xtrude model, with its zero-slip, low-shear operation is capable of extruding a variety of products with improved product appearance and a higher product quality. From potato rings and twists to corn chips and snacks, Marlen extruders are known as the leader for continuous pumping.

Features

- Designed specifically for continuous extrusion of shear sensitive materials

- Typical Applications: Corn chips, taco shells, tortilla chips, corn tortillas, masa curls, corn snacks

- Vacuum pump piston design provides even product appearance with fewer fines and spatters

- Creates the optimum product density with maximum oil absorption for higher product quality, taste and yield

- Increased capacity. Equipped with 6” pumping cylinders and 6” outlets connected to an 8” outlet which allows for even product flow at a uniform rate.

- The product is subjected to very little shear which maximizes yield by minimizing waste

- Designed to be fitted with an elbow and corn chip die assembly for a consistent product appearance

- Zero-slip design and low shear operation eliminates product degradation

- Minimizes waste. Less fines in the cooking oil decreases filtering and extends cooking oil life

- Marlen International also offers Marlen parts for our OPTI-Xtrude model

- Made in the USA

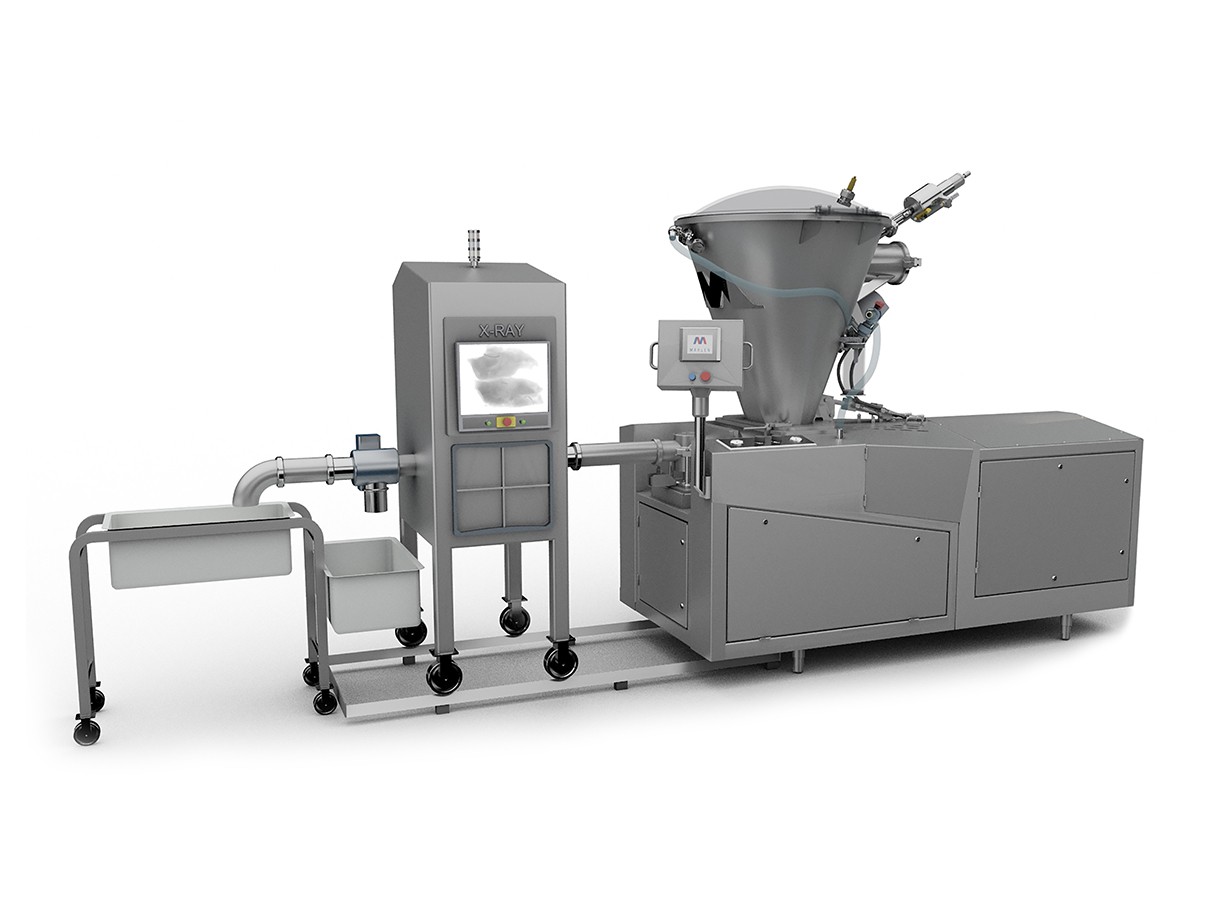

Opti Enclosed Pipeline X-ray Meat Inspection System

Is purge runoff from your meat x-ray system draining your yields? Our enclosed pipeline x-ray inspection system increased yields by 1.5 to 3%. An OPTI pump from Marlen pulls the strongest vacuum on the market and minimizes air pockets for greater imaging during the bone detection process. Uniquely designed for high-speed inspection of boneless whole muscle, trim and ground meat and poultry products. Up to 30,000 pounds per hour throughput.

Features

- Marlen OPTI model vacuum pump coupled with enclosed pipeline x-ray inspection unit

- Robust construction, designed for demanding US food manufacturing environments

- Smooth, gentle product handling

- Modular design for ease of cleaning, maintenance and reliability to maximize uptime

- Allen Bradley controls with PackML compliant data

COV Volumetric Portioner

The COV Volumetric Portioner is designed to volumetrically measure and portion whole muscle products with weight accuracy of ±0.5%. Available in 5, 10, 20, 40, and 60-lb. sizes. Ideal for any product which needs accurate portions of 0.5 to 60 lbs.

Features

- For portioning 0.5 to 60 pound quantities into bags, chubs, etc. It volumetrically measures the whole muscle, section/form or ground product, then delivers it at a controlled rate to the package. Coupled with a Marlen pump, the COV Volumetric Portioner can deliver up to 20 portions per minute.

- Weight accuracy of ±0.5%

- Available in 5, 10, 20, 40, and 60-lb. sizes

- Self-aligning actuator for decreased wear, less downtime & parts usage

- NEMA 4X cabinet eliminates water damage for less downtime

- 4″ unobstructed openings allow large whole-muscle products to pass undamaged giving better product quality

- Tilt bracket for COV body simplifies clean-up and results in more production time

- Easy weight adjustment for quick correction of weight variance and less product giveaway

- Electronically controlled

- USDA & CE Mark Approved

- Marlen International also offers Marlen parts for the COV Volumetric Portioner

- Made in the USA

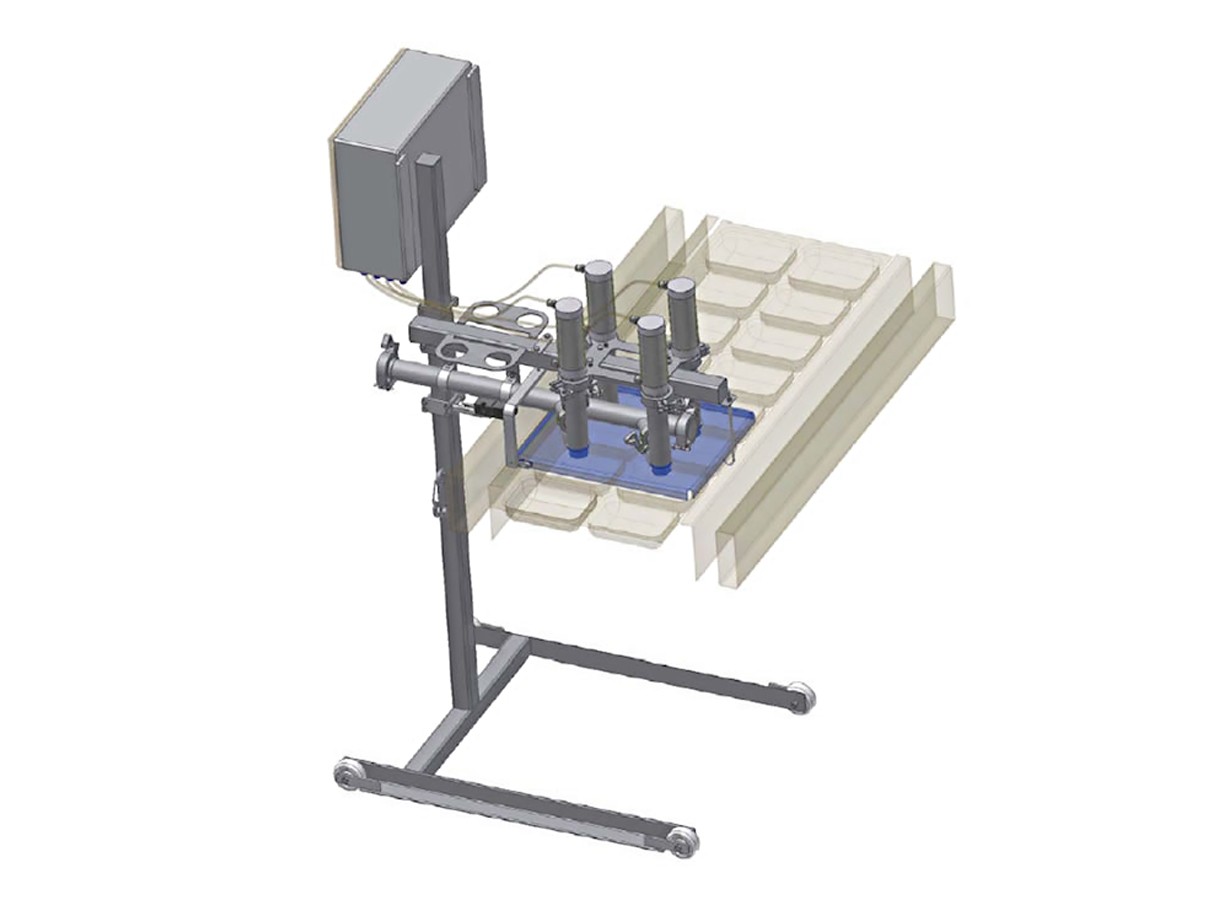

RS Volumetric Portioner

The RS Volumetric Portioner is custom designed to volumetrically measure and deliver specific portions into rollstock packaging machines. It measures, then rotates to deliver into the package. Ideal for any product that needs delivery of two accurate portions up to 15 lbs. per cycle.

Features

- Delivers two accurate portions

- Can portion up to 15 lbs per cycle

- Can be paired up with a roll stock packaging machine

- Marlen International also offers Marlen parts for the RS Volumetric Portioner

- Made in the USA

Transfer Valve Dynamic Portioner

The Transfer Valve assembly is designed to use the dynamic portioning within the Opti Transducer Portioning System (TPS), capable of delivery whole muscle portion with minimal damage and accuracy of ±2% average deviation.

Features

- The plug extends out of the body to dislodge product from the body

- Labyrinth seal grooves on the plug prevent dripping

- The plug shears material as it closes the opening

- Quick release clamp

- Marlen International also offers Marlen parts for the Transfer Valve Dynamic Portioner

- Made in the USA

Benefits of Vacuum Stuffing, Pumping & Portioning

Our twin-piston design allows for the gentlest handing to maintain product integrity while achieving high volume output.

- Superior particle definition and product integrity.

Our Opti stuffing and pumping system allows product to be diffused across the pump’s sheeting valve for the gentlest handling while maximizing vacuumization. This highly engineered design delivers premium whole muscle meats with the least amount of product damage.

- Optimal vacuumization.

Marlen’s patented twin-piston and sleeve design allow for maximum vacuumization throughout the system’s hopper and pumping chamber. By exposing the product to optimal removal of entrapped air and achieving up to 29” of mercury, better weight control is achieved, shelf life extended, and increased casing savings result through the delivery of denser products.

- Continuous flow.

Constant pressure and speed is maintained via Marlen’s hydraulic-powered and servo-driven pumps which retain the same pressure while stopped as when in motion. The result: a precise metered flow for better weight control at the speeds required for high volume production environments.