Confectionery depositors/extruders

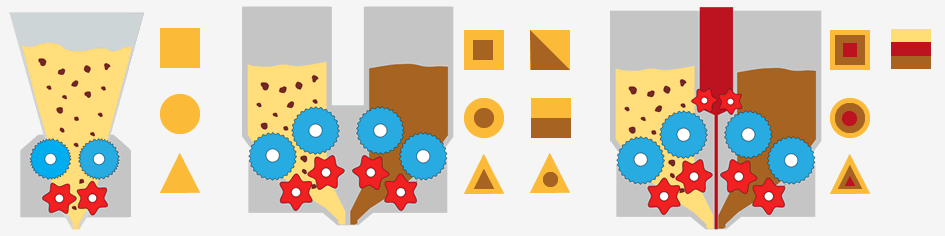

Single, double or triple extrusion

MAXON can extrude one, two or three masses at the same time.

MAXON Uno - a version with a single head for easy extrusion of one confectionery mass.

MAXON Duo - a version with a dual head for the extrusion of two confectionery masses at the same time.

MAXON Trio - a version with a triple head for the extrusion of three confectionery masses at the same time.

Industrial confectionery depositor/extruder MAXON Uno

-

- extruding one mass

- double pump

- working widths adapted to the production line

- heating or cooling the head

- intuitive touch control

- work in a prodution line

No compromise

MAXON is a versatile depositor / extruder for use in confectionery industry applications. MAXON is a powerful industrial machine, designed for shaping various types of confectionery products into ribbons for further cutting. MAXON is typically used for the manufacture of candy bars or pralines. MAXON has been designed to operate in conjuction with a tunnel oven or a cooling tunnel. MAXON is an extruder and depositor for the processing of, among others, confectionery masses with high fat content, pastries, pastes with additives. It is also suitable for pastes that require cooling or heating. With a variety of accessories, MAXON is a flexible machine for the production of a wide range of products.

Also suitable for heavier pastries and masses

Due to the use of unique gear pumps, apart from standard masses the machine can dispense pastries or harder and additives-containing masses (e.g. with nuts).

Heating and cooling

With an optional water jacket, which ensures a uniform temperature distribution, MAXON can be used for masses that require heating or cooling.

Operating width

MAXON can be designed in width adapted the existing systems (tunnel oven, cooling tunnel). Available operating widths are 800, 1,000, 1,200, 1,400, 1,500 or 1,600 mm.

Accuracy of dispensing

The machine allows for precise dispensing both in quantity range of pastry being fed and in its position on the conveyor belt.

Superior performance

Thanks to a unique design and high extrusion power, the performance of the machine is excellent.

Broad opportunities for development

With large selection of accessories the machine can be expanded and the manufactured product range adapted to the changing market.

Operation on the production line

MAXON operates in conjunction with other production equipment in the production line (tunnel ovens, cooling tunnels).

Intuitive control

An innovative icon-based touch-screen interface (no text) connected to mechanical buttons allows for unlimited creation of new patterns. USB port allows for saving and loading programs using external memory.

Easy change of tools

With special mechanisms and well-designed trolley, accessory head cleaning is very easy.

Hygiene

For easy cleaning, MAXON is made of durable materials approved for contact with food.

Industrial confectionery depositor/extruder MAXON Duo

- extruding two masses

- double pump for each mass

- working widths adapted to the production line

- heating or cooling the head

- intuitive touch control

- work in a prodution line

No compromise

MAXON is a versatile depositor / extruder for use in confectionery industry applications. MAXON is a powerful industrial machine, designed for shaping various types of confectionery products into ribbons for further cutting. MAXON is typically used for the manufacture of candy bars or pralines, also two-colour (consisting of two confectionery masses). MAXON has been designed to operate in conjuction with a tunnel oven or a cooling tunnel. MAXON is an extruder and depositor for the processing of, among others, confectionery masses with high fat content, pastries, pastes with additives. It is also suitable for pastes that require cooling or heating. With a variety of accessories, MAXON is a flexible machine for the production of a wide range of products.

Also suitable for heavier pastries and masses

Due to the use of unique gear pumps, apart from standard masses the machine can dispense pastries or harder and additives-containing masses (e.g. with nuts).

Heating and cooling

With an optional water jacket, which ensures a uniform temperature distribution, MAXON can be used for masses that require heating or cooling.

Operating width

MAXON can be designed in width adapted the existing systems (tunnel oven, cooling tunnel). Available operating widths are 800, 1,000, 1,200, 1,400, 1,500 or 1,600 mm.

Accuracy of dispensing

The machine allows for precise dispensing both in quantity range of pastry being fed and in its position on the conveyor belt.

Superior performance

Thanks to a unique design and high extrusion power, the performance of the machine is excellent.

Broad opportunities for development

With large selection of accessories the machine can be expanded and the manufactured product range adapted to the changing market.

Operation on the production line

MAXON operates in conjunction with other production equipment in the production line (tunnel ovens, cooling tunnels).

Intuitive control

An innovative icon-based touch-screen interface (no text) connected to mechanical buttons allows for unlimited creation of new patterns. USB port allows for saving and loading programs using external memory.

Easy change of tools

With special mechanisms and well-designed trolley, accessory head cleaning is very easy.

Hygiene

For easy cleaning, MAXON is made of durable materials approved for contact with food.

Industrial confectionery depositor/extruder MAXON Trio

- extruding three masses

- double pump for each mass

- working widths adapted to the production line

- heating or cooling the head

- intuitive touch control

- work in a prodution line

No compromise

MAXON is a versatile depositor / extruder for use in confectionery industry applications. MAXON is a powerful industrial machine, designed for shaping various types of confectionery products into ribbons for further cutting. MAXON is typically used for the manufacture of candy bars or pralines, also two- and three-colour (consisting of two or three confectionery masses). MAXON has been designed to operate in conjuction with a tunnel oven or a cooling tunnel. MAXON is an extruder and depositor for the processing of, among others, confectionery masses with high fat content, pastries, pastes with additives. It is also suitable for pastes that require cooling or heating. With a variety of accessories, MAXON is a flexible machine for the production of a wide range of products.

Also suitable for heavier pastries and masses

Due to the use of unique gear pumps, apart from standard masses the machine can dispense pastries or harder and additives-containing masses (e.g. with nuts).

Heating and cooling

With an optional water jacket, which ensures a uniform temperature distribution, MAXON can be used for masses that require heating or cooling.

Operating width

MAXON can be designed in width adapted the existing systems (tunnel oven, cooling tunnel). Available operating widths are 800, 1,000, 1,200, 1,400, 1,500 or 1,600 mm.

Accuracy of dispensing

The machine allows for precise dispensing both in quantity range of pastry being fed and in its position on the conveyor belt.

Superior performance

Thanks to a unique design and high extrusion power, the performance of the machine is excellent.

Broad opportunities for development

With large selection of accessories the machine can be expanded and the manufactured product range adapted to the changing market.

Operation on the production line

MAXON operates in conjunction with other production equipment in the production line (tunnel ovens, cooling tunnels).

Intuitive control

An innovative icon-based touch-screen interface (no text) connected to mechanical buttons allows for unlimited creation of new patterns. USB port allows for saving and loading programs using external memory.

Easy change of tools

With special mechanisms and well-designed trolley, accessory head cleaning is very easy.

Hygiene

For easy cleaning, MAXON is made of durable materials approved for contact with food.