experience, MARELEC offers grading solutions tailored to customers' specific needs. This could be for whole primals, portions or sections, fresh or frozen products. MARELEC graders can sort different sizes into fixed-weight trays or bulk packs. All equipment is built with robustness in mind and meets high standards of hygiene.

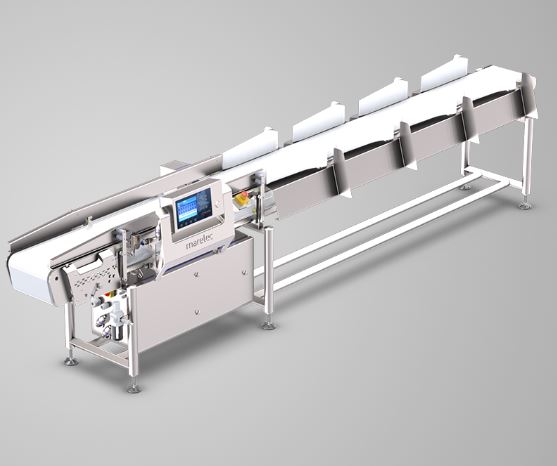

Compact grader

Grading Solution

Compact means infeed, weighing and grading on one belt and in one frame. The MARELEC M3 compact grader is an easy to use, simple and robust solution. This is combined with the same precision of classic graders.

Key benefits

- High accuracy

- High weighing and grading speed

- Robust and compact construction

- User-friendly

With the MARELEC M3 compact grader, MARELEC sets the new standard for smaller versatile grading systems using pull-arms. It is available with 6 or 8 stations, combined left and right. Options such as batching are available on request. The compact grader can be used on all kinds of meat products (Schnitzels, battered schnitzels, steaks, etc.).

Specifications

- Gates: 6 or 8

- Belt width: 250 or 300 mm

- Product weight: Up to 5 kg

- Max. product dimensions: Up to 290 x 400 mm

- Maximum capacity: 120 pcs/min.

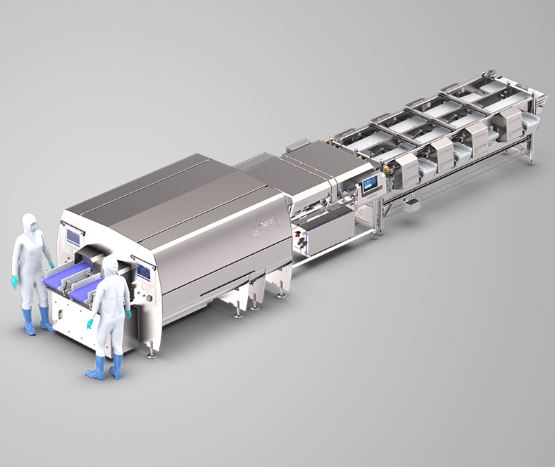

Custom grader

Grading Solution

The MARELEC Grading Solutions use state of the art weighing technology for creating highly advanced accurate and fast graders. MARELEC has many years of experience and offers grading solutions that specifically suits the customer's needs. All equipment is built with robustness in mind and a remarkably high standards of hygiene.

Key benefits

- Intelligent Batching Algorithm

- Modular concept

- Hygienic design

- Service

- Flexible design

MARELEC has a extensive experience in grading solutions. Each customer or situation is unique. With its solid background and experience in graders, MARELEC can offer a wide range of solutions for each customer's specific needs. MARELEC places a priority on openness with customers, in order to identify the needs and fulfil expectations.

All grading systems consist of three important components:

- Infeed:

The infeed system will generally determine the capacity of the grader. MARELEC offers a wide range of options for these systems. The perfect infeed system will be selected depending on the application (meat products) and requested capacity, ergonomics, and preliminary stages in the production process. - Weighing:

Meat products are mostly weighed dynamically. Precision and speed are the most important elements of the weighing system. MARELEC provides the solution, depending on dimensions and weight of the products. - Sorting and/or batching:

A variety of solutions are available depending on the type of meat products that need to be graded. The standard sorting systems are pull or push arm (flippers), retract conveyors and blow off. The sorting stations can be fully customized to customer's specific needs. These stations can be equipped with batching bins, presentation trays, tables, etc. Customized labels can be generated for each batch or tray by adding a label printer to the setup.

One or more take-away conveyors can be optionally used to transport the batches or trays to the following stage in the production process. The grading systems can be connected to the MATRIX software, which allows a full integration and traceability in the production line of the meat products.

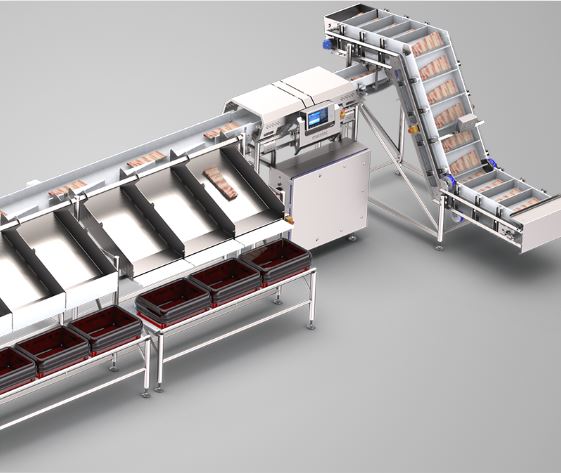

Grader after portioning

Grading Solutions

A grader after portioning will group different target weights together. MARELEC designs a variety of grader-after-portioning solutions that will suit the needs of your meat application.

Key benefits

- Reduction in manual labor

- Optimizes yield of the process

- Configurable by customer

- Feedback on weight to the portion cutter

The portion cutter provides the option to cut portions into multiple target weights and optimize yield. Optional tools and an acceleration conveyor enable the cut meat to be separated after the cutting machine.

Placing a grader after the portion cutter allows different target weights to be grouped together. Batches can be optionally created with these target weights.

The graders in line with a PORTIO consists of a wide range of designs. Customized solutions for special applications, e.g. trim tables, storage boxes etc. can be designed according to the customer's specific needs.

Beef grader

Grading Solutions

Beef Grading can be done on whole primals as well as on portions cut by our intelligent portion cutter. The MARELEC Grading Solutions combine state-of-the-art technology for highly advanced, accurate and fast grading.

Key benefits

- Ergonomic design

- Unparalleled accuracy

- Optimum product handling

- Robust and hygienic design

- Various infeed systems

- Customized weighing devices

- Integrated in turn key solutions

- Easy connection with MATRIX software

- Labor-saving options

Whole primals or portioned beef can be weighed and graded into different weight categories. After grading, portions can be transported directly to packaging machines or combined to a fixed weight pack.

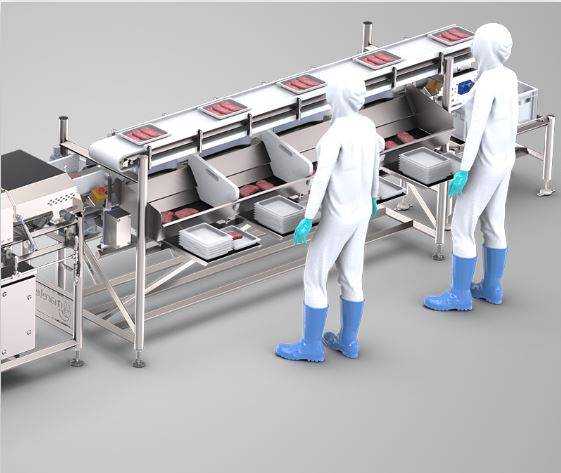

Pork grader

Grading Solutions

Pork grading can be done on whole primals such as loins, bacon, ribs, as well as on portions cut by our intelligent portion cutter. The MARELEC Grading Solutions combine state-of-the-art technology for creating highly advanced accurate and fast grading.

Key benefits

- Ergonomic design

- Unparalleled accuracy

- Optimum product handling

- Robust and hygenic design

- Various infeed systems

- Customized weighing devices

- Integrated in turn key solutions

- Easy connection with MATRIX software

- Labor-saving options

Whole primals or portioned pork can be weighed and graded into different weight categories. After grading, portions can be transported directly to packaging machines or combined to a fixed weight pack.

Lamb grader

Grading Solutions

The MARELEC Grading Solutions combine state-of-the-art technology for creating highly advanced, accurate and fast grading solutions.

Key benefits

- Ergonomic design

- Unparalleled accuracy

- Optimum product handling

- Robust and hygenic design

- Various infeed systems

- Customized weighing devices

- Integrated in turn key solutions

- Easy connection with MATRIX software

- Labor-saving options

Shanks, chops, or other cut-up parts can be weighed and graded into different weight categories. After grading, portions can be transported directly to packaging machines or combined to a fixed weight pack.