Portion Cutter PORTIO 1

Fixed-weight portion cutter

The fixed-weight portion cutter PORTIO 1 is used to portion flat products such as fish fillets to a programmed fixed weight with a vertical cut. This portioner for fish is also used to cut more rounded fish fillets or whole fish to a programmed fixed thickness.

Key benefits

- Optimized yield

- Unparalleled accuracy

- Modular belt

- Upgradable to PORTIO 3

- Adding options

- User-friendly software interface

- MATRIX P production reports

- Extremely hygienic, easy to clean

- Service

- Low noise

The fixed-weight portion cutter for fish PORTIO 1 uses the top camera to scan the volume of the fish fillet. The portioner can be upgraded by adding 2 side cameras to become a PORTIO 3. Bolt-on options are available to adapt the fixed-weight portioning machine over the operating life of the portioner in accordance with the evolution of your applications and processes.

Portion Cutter PORTIO 3

Fixed-weight portion cutter

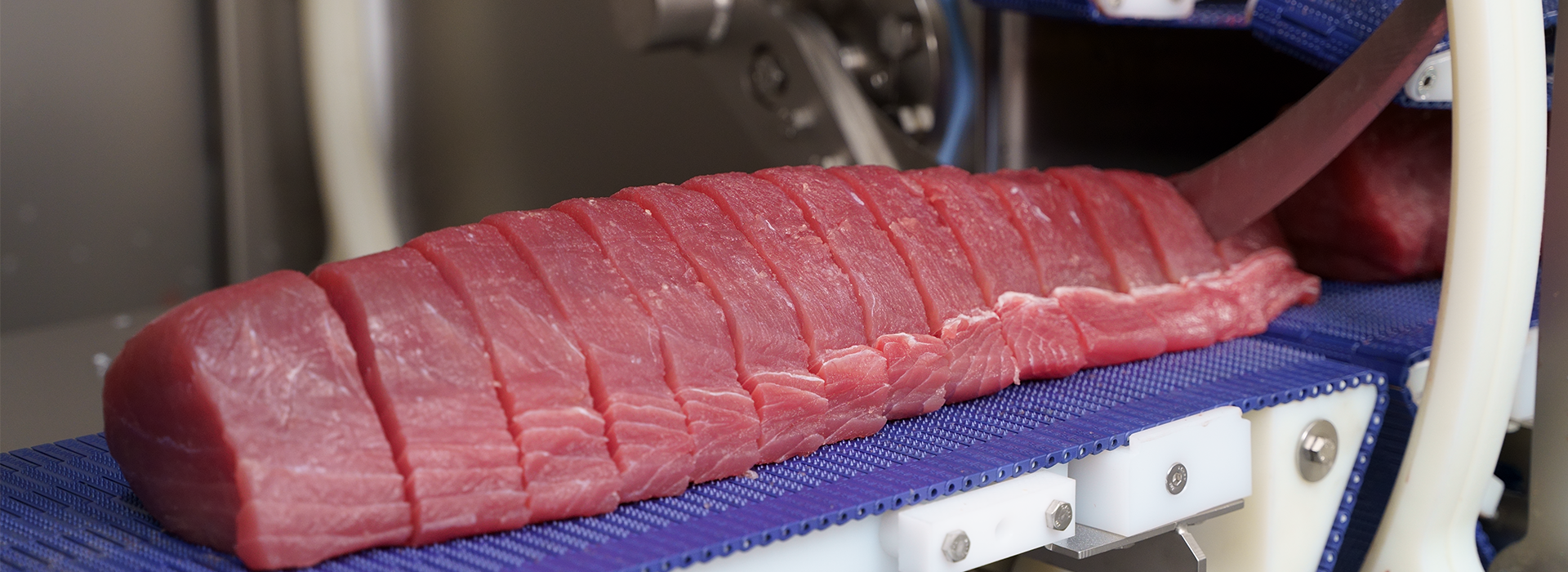

The fixed-weight portion cutter PORTIO 3 is used to portion rounded fish, such as tuna or fillets with an irregular shape or whole fish with a vertical cut to a programmed fixed weight. This portioner for fish PORTIO 3 uses 3 camera/laser combinations to accurately scan all around the whole fish or fish fillet.

Key benefits

- Optimized yield

- Unparalleled accuracy

- Modular belt

- Adding options

- User-friendly software interface

- MATRIX P production reports

- Extremely hygienic, easy to clean

- Service

- Low noise

The fixed-weight portion cutter for fish PORTIO 3 uses the top camera combined with the lateral side cameras to scan the volume of the larger fillets or whole fish. Bolt-on options are available to adapt the fixed weight portioning machine over the operating life of the portioner in accordance with the evolution of your applications and processes.

Specifications

- Lanes: 1

- Cameras: 3

- Belt width: 254 mm / 10 inches

- Max. product dimensions: 800 x 240 x 150 mm / 31.5 x 9.5 x 6 inches

- Max. cutting rate: 17 cuts/sec *

- Machine dimensions: 3425 x 1307 x 1569 mm / 135 x 52 x 62 inches

- Machine net weight: 1050 kg / 2315 lb

Portion Cutter PORTIO 1A

Fixed-weight portion cutter

The fixed-weight portion cutter PORTIO 1A is used to portion flat fish fillets to a programmed fixed weight. Fillets can be cut at an angle to maintain the natural look of the portioned fish fillets, or for a larger plate coverage. The knife angle of the knife can be changed from 0° to 30° or 45° with respect to the vertical position.

Key benefits

- Optimized yield

- Unparalleled accuracy

- Modular belt

- Automatic adjustment

- Upgradable to PORTIO 3A

- Adding options

- User-friendly software interface

- MATRIX P production reports

- Extremely hygienic, easy to clean

- Service

- Low noise

The fixed-weight portion cutter PORTIO 1A is used to portion flat fish fillets to a programmed fixed weight. Fillets can be cut at an angle to maintain the natural look of the portioned fish fillets or for a larger plate coverage. The knife angle of the knife can be changed from 0° to 30° or 45° with respect to the vertical position.

Specifications

- Lanes: 1

- Cameras: 1

- Cutting angle: 0/30/45°

- Belt width: 254 mm / 10 inches

- Max. product dimensions: 940 x 240 x 150 mm / 37.5 x 9.5 x 6 inches

- Max. cutting rate: 17 cuts/sec *

- Machine dimensions: 3502 x 1442 x 1569 mm / 138 x 57 x 62 inches

- Machine net weight: 1036 kg / 2284 lb

Portion cutter PORTIO 1DAP

Fixed-weight portion cutter

The dual-lane PORTIO 1 DAP has the highest capacity for portioning fish fillets with the smallest possible footprint. Fillets are cut at an angle for a natural look, or to obtain a greater plate coverage. The angle of the knife can be set in 5 positions.

Key benefits

- Optimized yield

- Unparalleled accuracy

- Modular belt

- Automatic adjustment on 5 knife positions

- Adding options

- User-friendly software interface

- Touch screen

- MATRIX P production reports

- Extremely hygienic, easy to clean

- Service

- Low noise

- Individual control

The dual-lane fixed weight portion cutter PORTIO 1 DAP uses a top camera on each lane to scan the volume of the fish fillet. It is typically used for portioning of fish cubes or fish slices from fresh fish fillets

Specifications

- Lanes: 2

- Cameras: 2 x 1

- Cutting angle: 0/15/30/45/50°

- Belt width: 229 mm / 9 inches

- Max. product dimensions: 950 x 210 x 60 mm / 37.5 x 8,5 x 2.5 inches

- Max. cutting rate: 25 cuts/sec *

- Machine dimensions: 3655 x 1922 x 1663 mm / 144 x 76 x 65 inches

- Machine net weight: 1800 kg / 3970 lb

Waterjet Cutter PORTIO JET

Waterjet Portion Cutter

The MARELEC PORTIO JET is a state-of-the-art waterjet cutter based on more than 15 years successful experience in portioning. The waterjet cutter is designed to portion fish fillets such as salmon or white fish into predetermined customized shapes while maintaining fixed weights.

Key benefits

- Unparalleled accuracy

- Optimized yields

- Intelligent cutting algorithms

- Modular design for increased capacity

- Extremely hygienic, easy to clean

- User friendly software interface

The PORTIO JET is developed to maximize yields when cutting predetermined shapes to fixed weights from fish fillets. The camera and laser combination scans to the highest accuracy and the intelligent cutting algorithm calculates the optimum cutting pattern. Typical applications include cutting salmon filets into fixed-weight loin portions, belly trim and tail section. By-products can be cut into strips and cubes. Whitefish fillets can also be portioned into several fixed-weight portions.

The MATRIX J software collects all production data from the PORTIO JET and allows it to generate production reports for each shift or program and to trace changes at machine level. MATRIX J software enables users to remotely take programs offline and monitor the status of the machine using an event log.

Specifications

- Lanes: 1 / 2

- Cameras: 2 top cameras

- Belt width: 600mm / 23.6 inches

- Max. product dimensions: 800 x 580 x 70 mm / 31.5 x 22.8 x 2.75 inches

- Maximum pressure: 3800 bar / optional 6000 bar

- Max. cutting rate: Depending on application and number of cutting stations