construction the equipment exceptionally reliable.

Scales

MARELEC offers a wide range of weighing indicators that can be combined with a weighing platform that is suitable for the job. Speed, accuracy, and reliability are the key-words for our weighing scales.

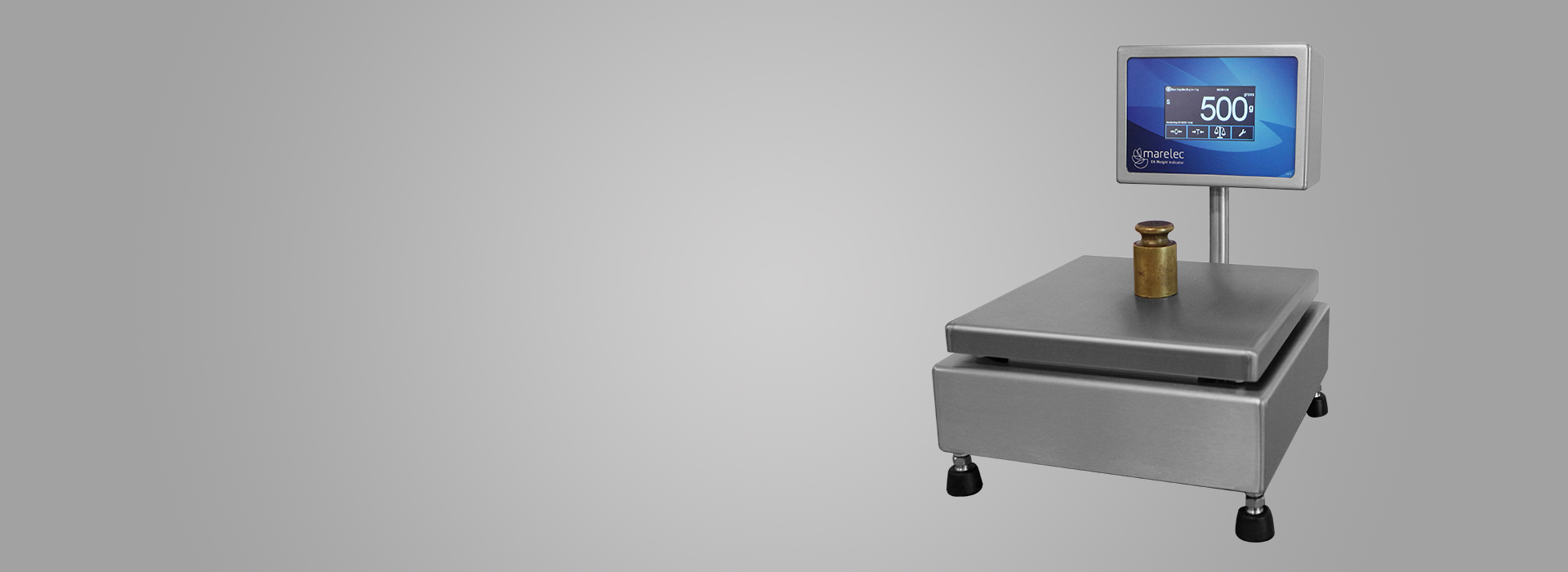

D6 Weighing Indicator

Intelligent weighing system

The MARELEC D6 Weighing Indicator is an intelligent, robust, and easy-to-use weighing instrument. A variety of weighing platforms are available, which each have a certain size and weighing range.

Key benefits

- Accurate Weighing

- Robust construction and waterproof

- Connectivity to MATRIX

- User-friendliness

The MARELEC D6 Weighing Indicator allows you to weigh products with the best possible accuracy without compromising on robustness and user-friendliness. This high-end indicator is IP 67 class and has a stainless steel AISI 316L which means it can withstand a washdown environment.

This weighing system can be equipped with a series of options such as printing, a grading function, reverse weighing, and data processing with a reporting module which can be adapted to customers' specific needs.

The indicator can also be powered by a 24 V battery.

Specifications

- Accuracy down to 1gr (E1), depending on weighing platform

- Stainless steel, type AISI 316L platform

- Indicator: 4.3" LCD display with touchscreen selection

- Power supply: single phase 230 VAC or optional 24 VDC batteries

- Connectivity to MATRIX

D100 Weighing Indicator

Intelligent weighing system

The MARELEC D100 is an intelligent product selection keyboard. It is robust and easy to use. With a few touches of the indicator, you can select the species, size, quality, and presentation.

Key benefits

- Robustness

- 48 standard species, up to 100 programmable species

- Up to 1500 programmable species/size combinations

- Very intuitive GUI with touchscreen

- Production management software

- Customized design

The MARELEC D100 Weighing Indicator allows you to weigh products with the best possible accuracy without compromising on robustness and user-friendliness. The touchscreen allows you to select the quality, size, and species. This data can be transferred to our MATRIX software and can then be used to optionally print labels. It is also possible to create reports and integrate conversions such as weight/loss factors.

Specifications

- Accuracy: < 0.1%

- Speed: < 1 sec

- Capacity: Several models, up to 75 kg

- Touchscreen 21.5-inch FHD

- TCP/IP connection

WT - Weighing Terminal

Intelligent weighing system

MARELEC's weighing terminal is a customized setup that can be used to manually control or create batch weights during certain stages in a production process. The terminal will communicate with MATRIX and is able to display or send data to the database that leads the production process.

Key benefits

- Robustness

- Very intuitive GUI with touchscreen

- Part of the bigger picture through interface with MATRIX

- Customized design

The setup mainly consists of a weighing plate that is combined with a 21.5-inch touchscreen and optionally a label printer. The intuitive GUI displayed on the touchscreen offers the following possibilities:

- Register or change batches into the production process and optionally allocate them to an order

- Consult the orders to be processed

- A label can be optionally printed for putting on the box that will leave the terminal

The MARELEC WT also offers the possibility to correct the weight in any trays rejected by a checkweigher system. The operator can manually correct the batch weight and adjust this in the database used in the production flow.

MARELEC WT is always combined with MATRIX PRO and is specially designed to be a part of a process flow.

Specifications

- Accuracy: 0.1%

- Speed: < 1 sec.

- Touchscreen 21.5-inch FHD

- TCP/IP connection

Flowscale

Dynamic weighing of product streams

These systems are able to accurately weigh a flow of products, e.g. pelagic fish or ice, over a certain period of time. This eliminates the need to collecting raw material in trays or tubs for weighing and gives a continuous raw material throughput.

Key benefits

- High accuracy

- Weighing a flow

- Robust construction

- Fast weighing

MARELEC offers a range of suitable standard-width flowscales, depending on the setup and throughput.

The flowscales are equipped as standard with a Z2 indicator which registers the weights and communicates with the network.

When using multiple flowscales and/or graders, the yield of different stages in the factory can be determined (e.g. weighing before and after gutting or filleting). The data from the weighing equipment is collected in different steps and processed by Matrix Yield. The yield between the different steps is an instant KPI that can be used to determine which equipment needs to be adjusted or fine-tuned.

Specifications

- Precision: 1%

- Capacity: 10 -100 tons/hour

- Conveyor speed: 0.3 - 0.5 m/s

- Widths of the standard models: 300/400/600/800 mm